Electric Materials

Ceramic Substrates

offering one-stop substrate making to customers

We have the top share in the global market for chip resistor substrates

Products

The chief products and technologies that we provide

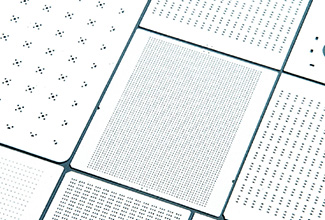

Alumina Substrates

We make alumina substrates for chip resistors, developed using our company’s accumulated sintering and sheet formation technologies. We have advanced technology for thin and strong substrates.

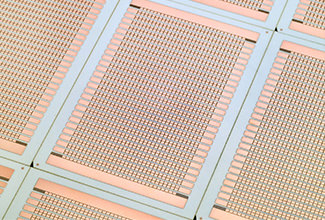

Thick-Film Printing Substrates

Using our printing technology on alumina ceramic substrates, we achieve high quality and high function thick-film printing substrates. We have production facilities with outstanding productivity, reliability, and functionality.

Needs

Our substrates are used in all types of electric products

Ceramic substrates are mounted and used in all types of electric products, as the circuit board of a chip’s resistors on which electronic components are mounted.

Advantage

Nippon Carbide Industries is the pioneer alumina product maker

Factory

At each of our factories, there are outstanding facilities that carry out all the production steps, so that we offer one-stop substrate making to customers

-

JAPAN

HOKURIKU CERAMICS CO., LTD.

Hokuriku Ceramics Co. is a subsidiary of Nippon Carbide Industries. At this company’s main factory in Uozu City, Toyama Prefecture, alumina-based materials are blended, green sheets are produced, and production technology is developed.

-

JAPAN

HOKURIKU CERAMICS CO., LTD. Namerikawa Factory

Hokuriku Ceramics Co. is a subsidiary of Nippon Carbide Industries.

At this company’s factory in Namerikawa City, Toyama Prefecture, thick film printing and new product development is carried out. All of the facilities for the production steps of thick film printing have been designed to achieve high productivity, reliability, and functioning. -

Thailand

ELECTRO CERAMICS(THAILAND)CO., LTD.

More than 30 years ago, we established a factory in Chiang Mai, Thailand for alumina substrate production. It is capable of performing at least as well as our domestic factories, in manufacture of white substrates and in thick film printing. More than 1,000 people work at this factory.

Line up

-

Ceramic Substrates

-

Alumina SubstratesFor Chip Resistors and so many kinds of Electronic Products

-

Thick-Film Printed SubstratesFor Hybrid IC, Quartz Crystal Oscillators, MEMS, Communication Equipment, Electro-Devices, Electronic Power Sources, Sensors, Electro-Devises for Automobiles, etc.

-

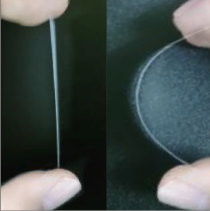

Thick-Film Printed Substrates with Thinner Thickness oneWearable, CSP, SAW Filter, Smaller Electronic Products, etc.

-

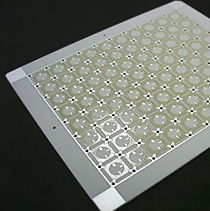

Alumina Substrates for LED with High ReflectivityLED Light, Backlight unit for LCD, Flash Light for Cellular Phone, Lightning for Automobile, etc.

-

-

Green Sheetings Manufacturing Subcontract

- Tel

- +81-3-5462-8207

- Fax

- +81-3-5462-8273

Reception time 9:00〜12:00/13:00〜17:30

(Except Saturday, Sunday and holidays)